3d Laserscanning

1Advantages

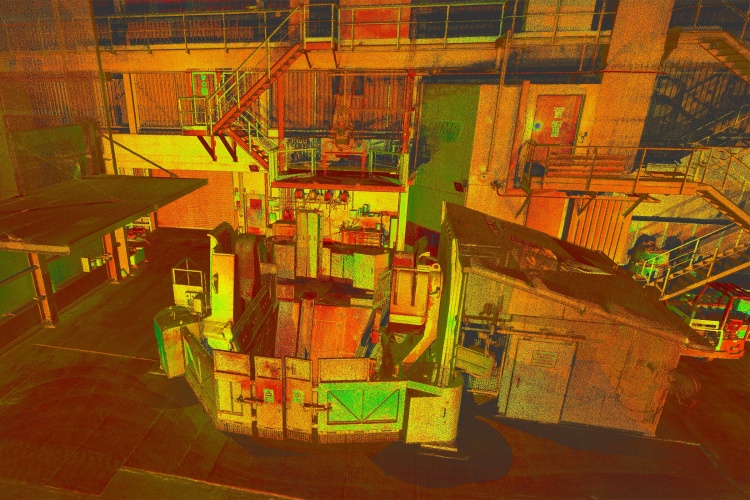

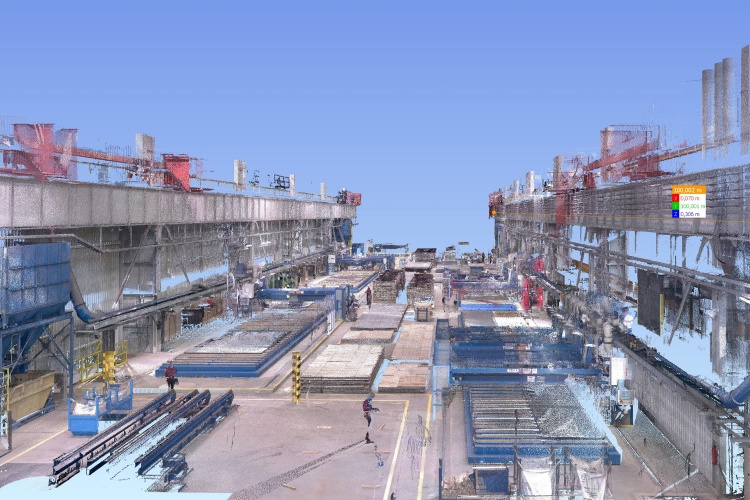

Thanks to the precise and easy to use 3D technology, we can scan complete factory halls within a few hours. The resulting point cloud offers particular advantages for brownfield projects.

Time-consuming on-site measurements and possible travel times are eliminated after the first scan. All interfering contours and exact dimensions can be easily determined in the office. New equipment can thus be quickly planned into existing environments.

2Fields Of Application

- Planning and discussion on the real model

- Brownfield projects with complex interfering contours

- Realistic floor plans

- Review of layouts

- Efficient as-built documentation (hydraulic areas, foundations, etc.)

- Comparison of actual contours with 3D models

- Determine hard-to-reach dimensions effortlessly

- Angled areas such as hydraulic spaces